Ahmetli, Gülnare

Loading...

Profile URL

Name Variants

Ahmetli, G.

Ahmetli, Gulnare

Ahmetli, Gulnare

Job Title

Email Address

gahmetki@ktun.edu.tr

Main Affiliation

02.01. Department of Chemical Engineering

Status

Current Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

2

ZERO HUNGER

1

Research Products

3

GOOD HEALTH AND WELL-BEING

2

Research Products

4

QUALITY EDUCATION

1

Research Products

6

CLEAN WATER AND SANITATION

4

Research Products

7

AFFORDABLE AND CLEAN ENERGY

6

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

7

Research Products

11

SUSTAINABLE CITIES AND COMMUNITIES

1

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

7

Research Products

13

CLIMATE ACTION

2

Research Products

14

LIFE BELOW WATER

1

Research Products

Documents

85

Citations

1806

h-index

23

This researcher does not have a WoS ID.

Scholarly Output

57

Articles

40

Views / Downloads

1/1

Supervised MSc Theses

6

Supervised PhD Theses

0

WoS Citation Count

460

Scopus Citation Count

527

WoS h-index

13

Scopus h-index

14

Patents

0

Projects

0

WoS Citations per Publication

8.07

Scopus Citations per Publication

9.25

Open Access Source

17

Supervised Theses

6

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Industrial Crops and Products | 4 |

| Journal of Applied Polymer Science | 4 |

| International Journal of Biological Macromolecules | 4 |

| JOURNAL OF APPLIED POLYMER SCIENCE | 3 |

| International Journal of Environmental Science and Technology | 3 |

Current Page: 1 / 6

Scopus Quartile Distribution

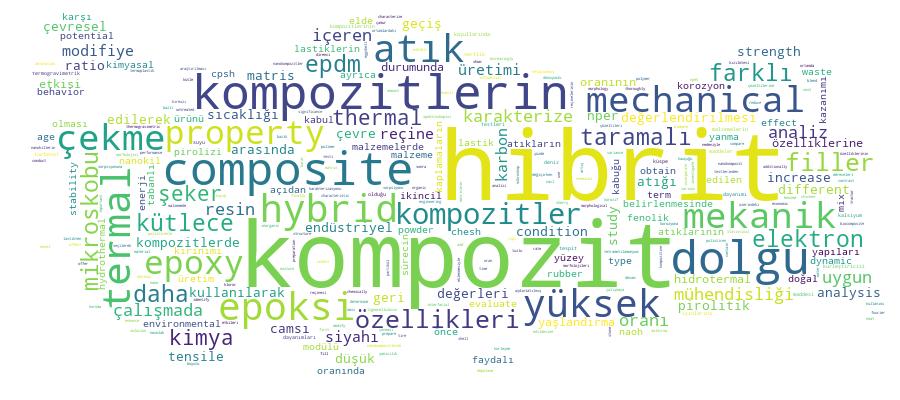

Competency Cloud

57 results

Scholarly Output Search Results

Now showing 1 - 10 of 57

Article Citation - WoS: 13Citation - Scopus: 14Red Mud Waste/Nanoclay Epoxy Hybrid Composites: Mechanical, Thermal, and Flammability Properties(Wiley, 2023) Özmeral, Nimet; Soydal, Ülkü; Kocaman, Süheyla; Ahmetli, GülnareIn this study, bisphenol A-type epoxy (ER) and epoxy phenol novolac resins (EPN) with two amine-type curing agents (KH 816 and IPOX EH 2041) having different total amine values were selected. The mechanical properties and density of the EPN resin were found higher in the case of both curing agents. EPN was modified with polystyrene (EPN-PS) and used as a matrix using an IPOX hardener. Nano- and hybrid composites were prepared with pristine and modified with tetramethylammonium chloride nano montmorillonite (NC and MNC), and red mud waste (RMW). The chemical structure was elucidated by the Fourier transform infrared (FT-IR). The composites were characterized by scanning electron microscopy and x-ray diffraction. Appropriate PS and NC ratio was accepted as 4% and 2% by weight, respectively. Curing degrees calculated from the FT-IR spectra of ER, EPN, and EPN-PS were 99.3%, 99.9%, and 86.5%, respectively. A comparative study of the two binary systems; (i) 2 wt% NC-(15-35) wt% RMW; and (ii) 2 wt% of MNC-(15-35) wt% of RMW on the mechanical, thermal, and flammability properties of EPN-PS matrix was carried out. The appropriate RMW ratio was 30 wt%. Hybrid composites with 25-30 wt% RMW can be considered self-extinguishing materials.Master Thesis Kompozit Malzemelerde Şeker Üretimi Atıklarının Değerlendirilmesi(2025) Kara, Musa; Ahmetli, GülnareEndüstride ham maddeler belli bir amaca göre işlenirken geriye kullanılmayan atık maddeler ortaya yardımcı olacaktır. Bu çalışmada dolgu maddesi olarak şeker üretimi atıkları: kireçleme aşaması çökeltisi olan kalsiyum karbonat atığı ve şeker pancarı küspesi, kompozit malzemelerin hazırlanması için kullanılarak kompozit yapımında değerlendirilmiştir. Kompozitlerin hazırlanmasında fenolik epoksi reçine (FER) matris olarak, anhidrit ve amin türü bileşikler ise 2 farklı kürleştirici olarak kullanılmıştır. Kompozitlerin mekanik ve termal özelliklerine, farklı dolgu maddelerinin ve kürleştiricilerin etkisi incelenmiştir. Kompozitlerin morfolojik yapıları taramalı elektron mikroskobu (SEM) ile, termal özellikleri TGA ile karakterize edilmiştir. Mekanik özelliklerin belirlenmesinde çekme ve sertlik testleri uygulanmıştır. Her 2 tür kompozit için de en uygun dolgu oranı %20 olarak belirlenmiştir. En yüksek çekme dayanımı değerleri KK kompozitlerinde görülmüştür. Benzer şekilde, KK kompozitleri daha yüksek termal dayanım sergilemişlerdir. KK kompozitlerinin çekme dayanımları %20 dolgu oranı ve MNA kürleştiricisi durumunda 96 MPa, KH 816 kürleştiricisi durumunda ise 84 MPa olarak bulunmuştur. Küspe kompozitlerinin çekme dayanımları ise %20 dolgu oranında MNA ve KH 816 kürleştirileri durumunda sırasıyla 79 MPa ve 75 MPa olarak belirlenmiştirçıkmaktadır. Bunlardan biri de şeker fabrikalarının atık maddesi olan küspe ve karbonatlama çamuru (KK) atıklarıdır ve bunların farklı ürünlerde değerlendirilmesi çevre sorununun çözümüne de.Article Citation - WoS: 2Citation - Scopus: 2Elastic and Acoustic Properties Determination of Epoxy/Polystyrene Mud Waste Hybrid Composites by Ultrasonic Method(Wiley, 2025) Oral, Imran; Ozmeral, Nimet; Ahmetli, Gulnare; Guzel, HaticeUltrasonic methods are more sensitive to defects such as voids, pores, and discontinuities that can diminish the true elastic and acoustic properties of materials compared to destructive testing. Therefore, the elastic properties and some acoustic properties of the epoxy phenol novolac modified with polystyrene (EPN-PS) matrix-based nano- and hybrid composites were determined for the first time using ultrasonic method. Montmorillonite-type nanoclay (NC) and industrial red mud waste (RMW) at a rate of 1-4 and 15-35 wt% respectively, were used as fillers in the composite preparation. According to the results, the highest elastic coefficient values (L = 8.14 GPa, G = 1.76 GPa, K = 5.79 GPa and E = 4.80 GPa) were obtained in the EPN-PS/NC1 (with 1 wt% NC) nanocomposite sample compared to the elastic properties of pure EPN and EPN-PS, while the highest elastic coefficient values (L = 8.97 GPa, G = 2.19 GPa, K = 6.06 GPa, and E = 5.86 GPa) among hybrid composites (HC) were obtained for the HC35 containing 2 wt. % NC and 35 wt% RMW. Due to both its high elastic and good acoustic properties, wall panels and floors produced using HC35 hybrid composite can be used for sound insulation in noisy environments.Highlights First evaluation of the acoustic characteristics of epoxy phenol novolac modified with polystyrene-nanoclay/red mud waste (EPN-PS-NC/RMW) composites. NC4 with 4 wt% nanoclay showed the lowest elastic and acoustic properties. Nanoclay ratio above 1 wt% reduces elastic and acoustic properties. The increasing RMW ratio in hybrid composites increases elastic properties. High elastic and acoustic properties make HC35 ideal for sound insulation.Article Citation - WoS: 12Citation - Scopus: 14Characterization of Unmodified and Modified Apricot Kernel Shell/Epoxy Resin Biocomposites by Ultrasonic Wave Velocities(Springer, 2022) Oral, İmran; Kocaman, Süheyla; Ahmetli, GülnareThe main goal of this research was to develop highly durable, low-cost eco-friendly biocomposites from apricot kernel shell (AKS) wastes and ultrasonic characterization of AKS-based obtained biocomposites. Natural AKS wastes were chemically modified using 5 wt% sodium hydroxide (NaOH) and 99 wt% glacial acetic acid (AA). These modified apricot kernel shells (MAKS) and unmodified apricot kernel shells (UMAKS) were added into bisphenol-A type epoxy resin (ER) in varied compositions such as 10-50 wt% to prepare the MAKS/ER and the UMAKS/ER biocomposites. The epoxy resin-mixture in the weight ratios of resin/hardener/accelerator was 100:30:1. The effect of AKS powder ratios and modifiers on the elastic properties (Young's moduli [E], bulk moduli [K], longitudinal moduli [L], shear moduli [G], and Poisson's ratio [mu]), density (rho), damping properties (attenuation coefficient [alpha], loss tangent [tan delta], and quality factor [Q]), ultrasonic micro-hardness (H), and acoustic impedance (Z) of biocomposites was investigated by the ultrasonic testing (UT) method. The morphological structure of the ER and biocomposites was figured out using scanning electron microscopy (SEM) and X-ray powder diffraction (XRD). The results revealed an increase in elastic properties of most of the AKS/ER biocomposites compared to the neat ER. On the other hand, results have shown that SEM and XRD images' analysis confirmed the amorphous structure of ER and biocomposites. The highest rho, v(L), v(S), L, G, E, H, and Z values were obtained in MAKS-AA/ER-5 biocomposite. Thus, it can be stated that the MAKS-AA/ER-5 biocomposite sample has the best mechanical properties. Also, the results revealed that the MAKS-AA/ER-1 sample can be used as an alternative material for its high Q-factor value instead of wood in producing musical tools.Article Citation - WoS: 2Citation - Scopus: 3Development of Sustainable Resource Recovery Approach From Agro-Industrial Wastes by Revealing the Economic Added Value Potential(Springer Nature, 2024) Goktepeli, G.; Ozgan, A.; Onen, V.; Ahmetli, G.; Kalem, M.; Yel, E.The physicochemical sludge generated from treatment of effluents from marble processing facilities should be managed properly due to their adverse effects on the environment. These sludges can be evaluated as catalyst in pyrolysis since they consist of some inorganics such as CaCO3 and Al or Fe salts which come from marble structure and coagulation–flocculation treatment of the effluent, respectively. Therefore, in this study, an approach for sustainable resource recovery from agro-industrial wastes (olive pomace) was developed by offering a solution to the two different waste types via pyrolysis and by revealing economic value-added potential of the process. Olive pomace-marble sludge catalyst mixtures were pyrolyzed in a laboratory-scale fixed bed batch pyrolysis system by using four catalyst dosages (10, 20, 30 and 50%) and three pyrolysis temperatures (300, 500 and 700 °C) at 5 °C/min heating rate. Pyrolysis oils and gases were analyzed with GCMS-FID and FTIR for evaluating the potential of economically valuable organic compounds. Organic compounds having extensive usage areas, such as feedstock for surfactants production, emollient, flavoring and softening, and high economic value in the market, such as 1-Pentadecanol, 2-Pentadecanone and Octane, were identified especially in catalytic pyrolysis liquid products. For instance, the potential profit that can be obtained from the conversion of olive pomace to ‘2-pentadecanone’ compound found in catalytic pyrolysis oil produced in this study is around 2.46 × 1013 USD for 2021/22 years at ideal conditions. Consequently, the presented approach contributes to sustainable circular economy via converting wastes into economic value instead of conventional waste disposal methods. Graphical abstract: (Figure presented.). © The Author(s) under exclusive licence to Iranian Society of Environmentalists (IRSEN) and Science and Research Branch, Islamic Azad University 2024.Article Citation - WoS: 8Citation - Scopus: 8Marble Processing Effluent Treatment Sludge in Waste Pet Pyrolysis as Catalyst-I: Pyrolysis Product Yields and the Char Characteristics(Springer, 2022) Önen, V.; Ozgan, A.; Göktepeli, G.; Kalem, M.; Ahmetli, G.; Yel, EsraThe processing and evaluation of industrial wastes together with other wastes may help material to remain in the system longer within circular economy. This study aimed to evaluate marble processing effluent physicochemical treatment sludge (K1) as catalyst in the waste poly(ethylene terephthalate)-PET pyrolysis. The effects of K1 dose (10-50%) and target temperature (300, 500, 700 degrees C) on the pyrolysis product yields and char characteristics were investigated. Fixed bed batch pyrolysis system was used under nitrogen atmosphere. The pyrolysis gas, oligomer and char product quantities changed in the range of 10.2-43.9, 2.42-21.9 and 23.5-83.8%, respectively. The increase in the K1 dose increased the char and decreased the liquid amount. Thermal, chemical, mineralogical characterization and proximate analyses were applied to char products. PET + K1 mixtures' chars mainly contain calcium carbonate (CaCO3), dolomite (CaMg(CO3)(2)), Ca(OH)(2), CaO, calcite (Mg0.03Ca0.97)(CO3). The char humidity and heat values decreased with increasing K1 doses. The residual value at 900 degrees C for PET waste was 14.2% while for PET + K1 mixtures it varied between 15.2 and 33.9%. Thermal degradation residual percentages of the 500 degrees C pyrolysis chars varied between 79.2 and 58.8%. K1 increased the thermal stability of the char, and this can provide it new areas of use. For example, when thermally stable char is needed with low pore volume and low surface area, K1 dose between 30 and 50% and the pyrolysis temperature of 500 degrees C can be suggested. By using K1, the variety of chars having different characteristics was obtained which transformed K1 and chars economic value as second-generation solutions.Article Citation - Scopus: 1Marble Processing Effluent Treatment Sludge in Waste Poly(ethylene Terephthalate) Pyrolysis as Catalyst–ii: Recovery From Pyrolytic Fluids(Institute for Ionics, 2024) Ahmetli, G.; Ozgan, A.; Onen, V.; Kalem, M.; Goktepeli, G.; Yel, E.In this study, feedstock and energy recovery potential from fluid fraction of catalytic pyrolysis of poly(ethylene terephthalate) plastic waste in the presence of marble processing effluent physico-chemical sludge catalyst were investigated. The contribution of the study is both symbiotic disposal of two kinds of wastes and produced valuable products. The pyrolysis fluid products obtained at 300–700 °C and 10–50% catalyst dose were inquired via chemical, thermogravimetric and chromatographic means. Main recoverable compounds were in the benzene group, followed by the esters, alcohols and ketones. The variety of organic components in pyrolytic gas was detected in aliphatic compounds (alkanes and alkenes) followed by the oxygenated organics and aromatic compounds. Benzoic acid, Methanone diphenyl(benzophenone), 1,1biphenyl, 9H Fluorene, Octane, Methyl benzene, some Benzene and Heptene derivatives were the components that are easily recoverable from the pyrolytic fluids. All these recoverable components are economically important feedstocks utilized in industrial processes. Optimization of recovery and enrichment methods of these compounds is recommended for further study. More thermally stable products formed and the higher final thermal residue of pyrolytic oil and oligomer products were obtained at higher pyrolysis temperatures. Their T5, T10 and T50 values varied between 36–44, 44–54, and 72–84 °C, respectively, while they were 131–154, 141–160 and 217–313 °C for oligomers. Calorific values of the produced oligomers were in the range of 5541–6984 cal/g. This study indicated that the thermochemical degradation of poly(ethylene terephthalate) with marble sludge catalyst is important approach for material and energy recovery in terms of fluid products of the process. © The Author(s) under exclusive licence to Iranian Society of Environmentalists (IRSEN) and Science and Research Branch, Islamic Azad University 2024.Article Citation - WoS: 26Citation - Scopus: 26Influence of Cotton Waste and Flame-Retardant Additives on the Mechanical, Thermal, and Flammability Properties of Phenolic Novolac Epoxy Composites(SPRINGER, 2021) Kocaman, Süheyla; Soydal, Ülkü; Ahmetli, GülnarePhenolic novolac-type epoxy (EPN) resin composites were fabricated by reinforcing with cotton waste (CtW), along with aluminum hydroxide (AH), and boric acid (BA) particles under different filler loadings. For characterization, thermogravimetric analysis, scanning electron microscopy, differential scanning calorimetry, and water sorption tests were performed on the composites. The effects of the CtW, AH, and BA contents on the thermal, flame-retardant, and mechanical properties of the composites were investigated. The triple hybrid additive (CtW:BA:AH) with a ratio of 20:5:10 wt% exhibited the best mechanical and combustion properties. The tensile strengths of this composite and the neat EPN were determined as 95.7 +/- 6.92 and 96.6 +/- 4.77 MPa, respectively. The T-50 temperatures of the BA- and AH-doped composites were higher than that of neat EPN. The highest char percentages were observed in the triple composites, while the lowest were observed in the EPN/CtW composites. The combustion of the triple composite with a CtW:BA:AH ratio of 20:5:10 wt% was spontaneously extinguished in 37 s. Horizontal flammability testing also showed better fire resistance for the CtW/BA/AH composites over their CtW counterparts, with the highest estimated limiting oxygen index of 32.3 obtained for the 20:5:10 wt% composite. The water sorption test results show that the CtW composites had the highest hydrophilicity, especially those with 30 wt% CtW or higher, in the presence of water at room temperature.Article Citation - WoS: 4Citation - Scopus: 4Enhanced Hydrogen Generation in Borohydride Hydrolysis Using an Efficient and Reusable Ia-Cnt Supported Co-Mo Catalyst(Elsevier Science Sa, 2025) Lakhali, Houssem; Kocaman, Sueheyla; Ahmetli, Gulnare; Ceyhan, Ayhan AbdullahThis study explored the synthesis and catalytic performance of an itaconic acid (IA)-modified, carbon nanotubesupported Co-Mo-B catalyst (IA-CNT@Co-Mo-B) for hydrogen generation via NaBH4 and KBH4 hydrolysis. The catalyst was tailored to improve efficiency and address renewable energy challenges. The catalyst's performance was evaluated by varying the catalyst amounts, temperatures, and concentrations of NaOH, KOH, NaBH4, and KBH4. Comprehensive characterization techniques were employed, including FTIR, XRD, FE-SEM/EDX, TEM, XPS, and BET. FE-SEM imaging revealed regions with highly ordered and aligned structures within the IA-CNT matrix, likely due to the effective doping of Co, Mo, and B. BET analysis revealed a significant surface area of 71.56 m(2) g(-1) and a pore diameter of 16.57 nm, categorizing the IA-CNT@Co-Mo-B catalyst as mesoporous, which enhanced its catalytic activity. This catalyst achieved high hydrogen generation rates (HGR) of 5.3 L g(metal)(-1) min(-1) with NaBH4 and 7.2 L g(metal)(-1) min(-1) with KBH4 at 30 degrees C. Activation energies were determined to be 24.58 kJ mol(-1) for NaBH4 and 20.38 kJ mol(-1) for KBH4, with respective reaction orders of 0.3 and 0.8. The reusability tests demonstrated stability over ten cycles, emphasizing its industrial potential for clean energy technologies.Article Catalytic Co-Pyrolysis of PET/PP Plastics and Olive Pomace Biomass with Marble Sludge Catalyst(2025) Kalem, Merve Sogancioglu; Yel, Esra; Goktepelı, Gamze; Önen, Vildan; Ahmetli, Gulnare; Özgan, AfraSürdürülebilir ve etkili atık yönetimi, çeşitli atık türlerine simbiyotik çözümlerin dahil edilmesini ve böylece dairesel ekonomiye ulaşılmasını gerektirir. Bu motivasyonla, bu çalışmada, plastiklerin, biyokütlenin ve mermer işleme atıklarının fizikokimyasal arıtma çamurunun (K1) kombine termokimyasal dönüşümü (pirolizi) incelenmiştir. Bu kombinasyonda, plastikler petrol bazlı sentetik aromatik (PET) ve alifatik (PP) organikler iken, zeytin posası-OP doğal tarımsal kalıntıdır. K1, literatüre ilk olarak yazarlar tarafından piroliz katalizörü olarak tanıtılan mineral üründür. Çalışmada, polimerlerin ve biyokütlenin eş pirolizi, CaCO3 içeren mineral atık tarafından katalize edilmiştir. Plastik türünün ve pirolize edilmiş malzeme karışım oranının piroliz fraksiyonları üzerindeki etkisi araştırılmıştır. Ayrıca, piroliz fraksiyonlarından malzeme geri kazanım potansiyeli tartışılmıştır. Katalitik ko-pirolizde, karışımdaki plastik oranının artırılmasıyla pirolitik sıvı ve oligomer fraksiyonu artarken katı (char) ve gaz fraksiyonu azaldı. %70PP+%15OP+%15K1 karışımı için sıvı ürün baskındı, %60PET+%20OP+%20K1 ile ise çok daha fazla pirolitik gaz fraksiyonu üretildi. Char ürünlerinin termal bozunması 600°C'ye kadar %2-3'ü geçmedi ve bu kararlılık yaklaşık 700°C'ye kadar devam etti, char'ın yüksek termal dirence sahip bir malzeme olarak alternatif alanlarda kullanılma potansiyelini ortaya koydu. Katalitik ko-piroliz sıvı ürünleri alkanlar, alkenler, asitler, fenoller, benzen, aldehitler, esterler, alkoller, ketonlar içerir. Sıvılarda benzen, asit ve alkol grupları baskınken, gazlarda alkan, alken ve alkin grupları baskındı.