Şahin, Ömer Sinan

Loading...

Profile URL

Name Variants

Sahin, Omer Sinan

Şahin, Ömer S.

Şahin, Ö. S.

Sahın, Ömer Sinan

Şahin, Ö. Sinan

Sahin, O. Sinan

Sahin, Omer S.

Sahin, O.S.

Sahin, O. S.

Şahin, Ömer S.

Şahin, Ö. S.

Sahın, Ömer Sinan

Şahin, Ö. Sinan

Sahin, O. Sinan

Sahin, Omer S.

Sahin, O.S.

Sahin, O. S.

Job Title

Email Address

ossahin@ktun.edu.tr

Main Affiliation

02.10. Department of Mechanical Engineering

Status

Current Staff

Website

ORCID ID

Scopus Author ID

Turkish CoHE Profile ID

Google Scholar ID

WoS Researcher ID

Sustainable Development Goals

7

AFFORDABLE AND CLEAN ENERGY

1

Research Products

9

INDUSTRY, INNOVATION AND INFRASTRUCTURE

4

Research Products

12

RESPONSIBLE CONSUMPTION AND PRODUCTION

2

Research Products

Documents

31

Citations

748

h-index

14

Documents

67

Citations

1499

Scholarly Output

42

Articles

27

Views / Downloads

0/1

Supervised MSc Theses

9

Supervised PhD Theses

2

WoS Citation Count

494

Scopus Citation Count

529

WoS h-index

12

Scopus h-index

12

Patents

0

Projects

1

WoS Citations per Publication

11.76

Scopus Citations per Publication

12.60

Open Access Source

18

Supervised Theses

11

Google Analytics Visitor Traffic

| Journal | Count |

|---|---|

| Polymer Composites | 5 |

| MATERIALS | 2 |

| Journal of Reinforced Plastics and Composites | 2 |

| Konya mühendislik bilimleri dergisi (Online) | 2 |

| Composite Structures | 2 |

Current Page: 1 / 5

Scopus Quartile Distribution

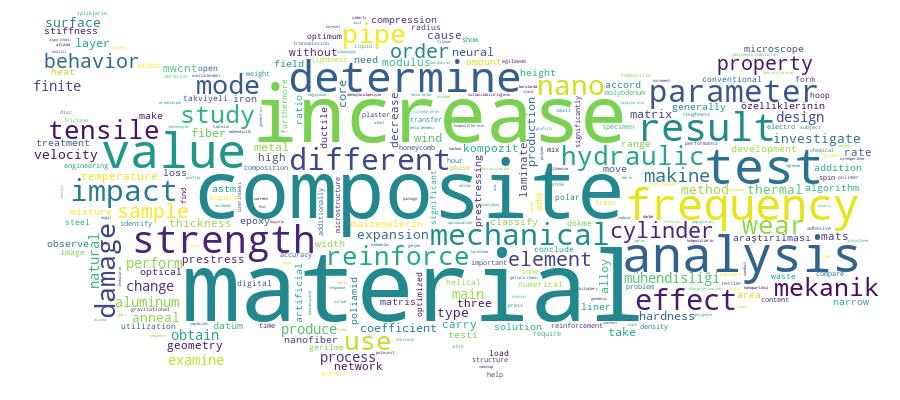

Competency Cloud

42 results

Scholarly Output Search Results

Now showing 1 - 10 of 42

Article Citation - WoS: 5Citation - Scopus: 4Comparison of Mechanical Properties of the Type 1 and Type 2 Composite Hydraulic Cylinder Designs: a Numerical Study(Wiley, 2023) Coşkun, Taner; Sahin, Omer SinanHydraulic cylinders can reach enormous sizes depending on the working pressure and application areas. These structures, which are typically fabricated using traditional steels, can be quite heavy, which can cause a number of issues, particularly low system efficiency and fuel performance. A Type 1 composite hydraulic cylinder (CHC) with geodesic dome trajectories was created in our earlier work, and the effects of composite material utilization on the structural weight and mechanical responses were examined. Furthermore, the applicability of the geodesic dome to the CHCs was examined, and the benefits and drawbacks of using the dome profile were found. A Type 2 CHC was created in the current study, and the structural performances of Type 1 and Type 2 CHCs were compared. In this regard, numerical analyses were done to assess the mechanical responses and structural performance of a Type 2 CHC. Additionally, utilizing response surface methodology (RSM), the design parameters were optimized. The outputs of the current study were then verified by comparing the outcomes of statistical-based RSM and FEM examinations. As a result, the structural weights for both designs were compared with steel hydraulic cylinders of the same strength, and it was revealed that Type 1 and Type 2 CHCs were 53.78% and 38.42% lighter than steel ones, respectively. In addition, the advantages and disadvantages of the design types were discussed, and thus the optimum design was determined by considering the application areas and requirements.Article Citation - WoS: 19Citation - Scopus: 19Investigation of the Effect of Surface Crack on Low-Velocity Impact Response in Hybrid Laminated Composite Plates(SPRINGER HEIDELBERG, 2020) Güneş, Aydın; Şahin, Ömer SinanComposite materials can be damaged in the environments in which they are used, due to the loads they are exposed to or due to different effects on the production processes. The formation processes of these damages generally develop as crack formation or progress of the existing crack. For this reason, it is very important to investigate the behavior of the crack that occurs after the dynamic loads to which the composite materials are exposed. In this study, the dynamic behaviors of hybrid laminated composites with different surface crack geometries were investigated. Surface cracks with different crack depth-to-thickness (a/t) and crack depth-to-crack width (a/c) ratios were machined upon hybrid composite laminates and subjected to low-velocity impact tests under 2 m/s, 2.5 m/s and 3 m/s impact velocities. The effect of different surface crack geometries upon variation of contact force versus time, variation of contact force versus displacement and variation of absorbed/rebound energy have been evaluated. The effect of surface crack geometry and impact velocity upon contact stiffness and bending stiffness was also evaluated. Damage formation during impact loading was examined by scanning electron microscopy and optical microscopy. After the evaluations, the damage behaviors caused by the dynamic loads depending on the initial surface crack geometry were examined in detail.Article Dynamic Responses and Damage/Element Composition Analysis of Thermoplastic Polyamide Reinforced Epoxy Composites Exposed To Hci Environment(Wiley, 2024) Coşkun, Taner; Sözen, Betül; Şahin, Ömer SinanThe present study aimed to examine how the corrosive environment affected the low-velocity impact (LVI) characteristics and damage mechanisms of thermoplastic polyamide fiber-reinforced polymer (PFRP) composites. In this regard, composite specimens were subjected to corrosive environment containing 10 wt.% diluted HCl for one week and one month before LVI tests. To investigate the hostile effects of the corrosive environment on the composites, scanning electron microscope (SEM) coupled with energy-dispersive X-ray system (EDX) analyses were carried out, and thus variations in the elemental composition and damage mechanisms for the composites were determined. According to the examinations, it was discovered that the degradation in LVI responses, such as contact stiffness, bending stiffness, and peak force, increased with longer aging time, as expected. Furthermore, when the aging effect was assessed based on absorbed energy, the specimens exposed to a corrosive environment for one month exhibited the highest energy absorption compared to the control and 1-week-immersed ones. The degrading effect of the HCI environment appeared as higher damage severity on the composites, which was also detected from the SEM images. According to the SEM analyses, matrix cracks, corrosion pits, and local surface imperfections caused by ion exchange are detected in 1-week-immersed specimens, while more serious damage mechanisms such as fiber breakage and fiber pull-out are noted in specimens exposed to corrosive environment for 1 month. Furthermore, approximately 6.33 wt.% CI was identified in the composites after 1 month of aging, which was associated with the hydrolysis triggered by rise in the composite's damage severity.Master Thesis Filaman Sarım Ctp Borularda Darbe Sonrası Basma (caı) Davranışının İncelenmesi(Konya Teknik Üniversitesi, 2019) Gemi, Dilek Soylu; Şahin, Ömer SinanFilaman sarım tekniği ile üretilen CTP (Cam Takviyeli Polimer) kompozit borular basınçlı kimyasal madde içeren sıvıların, endüstriyel sıvıların iletiminde, petrol ve doğalgaz iletimi ve çeşitli alanlarda konstriksiyon malzemesi olarak birçok alanda kullanılmaktadır. CTP kompozit borular gerek montaj gerekse servis esnasında çeşitli sebeplerden dolayı düşük hızlı darbelere maruz kalabilmektedir. Darbenin etkisiyle CTP kompozit boru cidarında; matris çatlağı, elyaf hasarı ve tabakalar arası ayrılma gibi gözle görülmeyen hasarlar meydana gelebilir. Darbe sonucu oluşan bu hasarlar ile mukavemet kaybına uğrayan kompozit borular, servis esnasında beklenen mukavemet değerlerini verememektedir. Düşük hızlı darbe sonrası oluşan hasarların incelenmesi ve bu hasarların kompozit borunun mukavemet kayıplarına etkisinin araştırılması için (±55°)3 konfigürasyonuna sahip üç farklı çapta (Ø54, Ø72 ve Ø96 mm) kompozit boru üretilmiştir. Düşük hızlı darbe hasarının etkisinin incelenmesi amacıyla, yukarıda belirtilen çaplardaki borular üzerine ASTM D 7136 standardına göre, 1.5, 2, 2.5 ve 3 m/s hızlarda darbe uygulanmış ve ön hasar oluşturulmuştur. Düşük hızlı darbe sırasında Kuvvet-Zaman, Kuvvet-Deplasman ve Enerji-Zaman grafikleri çıkartılarak boruların dinamik davranışları ve oluşan hasarlar incelenmiştir. Darbe sonrası borularda oluşan hasarların kalan mukavemete etkilerinin incelenebilmesi için ön hasarlı borulara ASTM D 7137 standardına göre Darbe Sonrası Basma (CAI) testleri yapılmış ve Kuvvet-Deplasman grafikleri elde edilmiştir. Elde edilen sonuçlar, darbe hasarsız numunelerin davranışlarıyla karşılaştırılmıştır. Düşük hızlı darbe ve darbe sonrası basma deneyleri sırasında elde edilen veriler ve oluşan hasarlar kaydedilmiştir. Deneyler sonrasında CTP boruların optik mikroskop ve SEM görüntüleme ile makro/mikro hasar analizleri yapılmıştırDoctoral Thesis Elektro-eğirme Yöntemiyle Üretilmiş Çok Cidarlı Karbon Nanotüp (çcknt) Takviyeli Polivinil Alkol (pva) Nano-keçe Barındıran Kompozit Levhaların Mekanik Davranışlarının Belirlenmesi(Konya Teknik Üniversitesi, 2020) Özten, Ünal; Şahin, Ömer SinanBu çalışmada, oda sıcaklığında elektro-eğirme yöntemiyle üretilmiş farklı oranlarda (ağırlıkça %1, %2 ve %3) Çok Cidarlı Karbon Nanotüp (ÇCKNT) takviyeli Polivinil Alkol (PVA) nano keçe barındıran cam elyaf kompozit levhaların mekanik özellikleri ve kırılma davranışlarının standart mekanik deneyler yardımıyla tayin edilmesi amaçlanmıştır. Bunun için ilk olarak, ÇCKNT takviyeli PVA kullanılarak elektro eğirme yöntemiyle nanoelyaf keçeler üretilmiştir. Üretilen nanoelyaf keçelerin morfolojik yapılarının incelenmesi amacıyla Taramalı Elektron Mikroskopisi (SEM) görüntüleri alınarak analiz edilmiştir. Son olarak, nanoelyaf keçelerden vakum yardımıyla reçine transfer kalıplama (VARTM) tekniği benzeri bir yöntem olan "Vakum Destekli Elle Yatırma Yöntemi" kullanılarak kompozit levhalar oluşturulmuştur. Üretilen PVA esaslı nano yapıların ve sonrasında üretimi gerçekleştirilen PVA nanoelyaf keçe barındıran kompozit numuneler standartlara uygun biçimde Çekme Testi (ASTM D 3039), Düşük hızlı darbe testi (ASTM D 7136), Üç noktadan eğilme testi (ASTM D 7264), Darbe sonrası basma testi (ASTM D 7137) gibi çeşitli mekanik testlere tabi tutulmuşlardır. Testler sonucunda kompozit levhaların mekanik davranışları incelenmiş ve mukavemet değerleri belirlenerek elde edilen sonuçlar mukayese edilmiştir. Son olarak, hasar görmüş numunelerin kırılma yüzeyleri optik ve dijital mikroskop yardımıyla incelenerek farklı oranlardaki ÇCKNT içeren PVA nanofiber takviyesinin numunelerde gelişen hasar davranışlarına ve gelişimlerine etkisi anlaşılmaya çalışılmıştır.Master Thesis Development and Mechanical Characterization of a Waste Polyamide-Reinforced Polymer Matrix Composite(2025) Arpınar, Müfit Samet; Şahin, Ömer SinanBu çalışmada, fabrika atığı olan poliamid ipliklerin katkısıyla çevre dostu ve ekonomik açıdan avantajlı yeni bir polimer matris kompoziti geliştirilmiş ve bu kompozitin mekanik özellikleri kapsamlı bir şekilde incelenmiştir. Araştırmanın ana hedefi, atık malzemelerin değerlendirilmesi yoluyla sürdürülebilirlik ve maliyet etkinliği sağlarken üstün performanslı malzemeler üretmektir. Reçine kompozitinin mekanik performansını belirlemek için çekme testi, üç noktadan eğilme testi ve sıyrılma testi gibi temel mekanik testler gerçekleştirilmiştir. Bu testler, eğilmede mukavemet, eğilmede elastiklik modülü, birim şekil değiştirme ve gerilme performansı gibi kritik parametreleri değerlendirmek için yapılmıştır. Çalışmada, farklı boyutlardaki poliamid ipliklerin kompozit malzeme üzerindeki etkileri araştırılmıştır. Analizler, deneysel parametrelerin malzemenin mekanik performansı üzerindeki etkilerini detaylı bir şekilde ortaya koymuştur. Sonuçlar, atık poliamid katkısının polimer matris kompozitin mekanik özelliklerine anlamlı katkılar sağladığını ve optimize edilmiş formülasyonların endüstriyel uygulamalar için güçlü adaylar olduğunu göstermiştir.Article Mechanical and Dynamic Characteristics for the Cfrp, Gfrp, and Hybrid Composites Exposed To Hcl Environment(Sage Publications Ltd, 2024) Coskun, Taner; Sozen, Betul; Kapici, Serkan; Sahin, Omer SinanIn the current study, the low-velocity impact (LVI) characteristics of carbon fiber-reinforced polymer (CFRP), glass fiber-reinforced polymer (GFRP), and hybrid composites before and after the corrosive environment exposure were investigated. In this regard, CFRP, GFRP, and hybrid composites were subjected to LVI and tensile loadings after being kept in a 10% diluted HCl environment for 1 week and 1 month, and the impacts of the corrosive environment on the composites' dynamic and mechanical responses were determined by comparing the outcomes of the control and aged specimens. LVI tests for CFRP, GFRP, and hybrid composites were carried out by transferring 25.2 and 11.2 J impact energy to the specimens with two impact velocities of 3 and 2 m/s, respectively, and thus, the effects of impact energy and hybridization were investigated. Moreover, tensile tests were conducted for the control and aged specimens with 2 mm/min crosshead speed, and thus, the effects of fiber material, hybridization, and corrosive environment on the mechanical properties were determined. The study found that CFRP composites had higher stiffness than GFRPs, whereas hybrid composites exhibited dynamic responses between CFRP and GFRP, as expected. On the other hand, it turned out that the composites absorbed most of the impact energy, which was interpreted as being absorbed by the damage of fiber-reinforced composites, which stand out with their brittle characteristics. Furthermore, it was discovered that the damage severity elevated as expected with a longer aging time, which was attributed to the corrosive liquid attacking the fibers, matrix, and fiber/matrix interfaces and reducing strength. It was also observed that, as predicted, the corrosive effects generally resulted in a reduction in tensile responses, including ultimate strain and tensile strength.Article Citation - WoS: 73Citation - Scopus: 79Experimental Investigation of the Effect of Diameter Upon Low Velocity Impact Response of Glass Fiber Reinforced Composite Pipes(ELSEVIER SCI LTD, 2021) Gemi, Dilek Soylu; Şahin, Ömer Sinan; Gemi, LokmanThe GRP (Glass Reinforced Polymer) composite pipes produced by filament winding technique are used in many fields such as the transmission of pressurized chemical liquids, industrial liquids, oil and natural gas transmission and construction materials. GRP composite pipes may be subjected to low velocity impacts for various reasons both during installation and service. The impact on the GRP composite pipe wall may lead to some nonvisible damages such as matrix crack, fiber damage, delamination and inter-layer separation. Composite pipes suffered strength loss due to these damages caused by impact cannot support the expected strength values during service. Pipes with three different diameters (054, 072 and 096 mm) were produced to investigate the damage caused by low velocity impact and to determine the effect of these damages on the strength losses of the composite pipe. In order to investigate the influence of low velocity impact damage, the produced pipes were subjected to impacts at the velocity of 1.5, 2, 2.5 and 3 m/s according to ASTM D 7136 and preliminary damage was formed. During low velocity impact tests, Force-Time, Force-Displacement and Energy-Time graphs were obtained and dynamic behavior of the pipes were examined. With the increase in diameter; it has been observed that the effect of low velocity impact is reduced and the damage after impact transformed into delamination damage rather than multiple damage.Article Citation - WoS: 1Citation - Scopus: 1Low Velocity Impact and Tensile Performance of Gfrps Interleaved With Electrospun Nylon 6,6 Nanofiber Mats(UNIV OSIJEK, TECH FAC, 2021) Yıldız, Murat; Yapıcı, Ahmet; Özkan, Vildan; Şahin, Ömer SinanNanofibers can be interleaved into polymers and improvements in mechanical properties such as resistance to impact, delamination and debonding as well as enhanced ductility can be obtained. In this work, GFRP laminated composites were interleaved to non-woven nylon 6,6 nanofiber mats which were generated by the electrospinning method. Four kinds of configurations were considered; two pure configurations where GFRP had two and four glass fiber layers and the other two kinds of nanofiber modified configurations that had one and three nylon 6,6 nanofiber mats being interleaved in GFRP. Those specimens were then investigated for their impact resistance, energy absorption and tensile strength capabilities in regard to low-velocity impact and tensile tests. The results showed that adding nylon 6,6 nanofiber mats can increase energy absorption values of the modified specimens, but some decrease in load capacities could be observed.Article Citation - WoS: 20Citation - Scopus: 21Effects of Geodesic Dome Trajectories on the Specific Strength of Composite Overwrapped Pressure Vessels: Fe Modelling(Pergamon-Elsevier Science Ltd, 2023) Coşkun, Taner; Şahin, Ömer SinanIn this study, it was aimed to find out geodesic dome trajectories of composite overwrapped pressure vessels, and investigate the effect of dome profiles on the structural performances. In this context, geodesic paths for 0.2, 0.3, 0.4, 0.5 and 0.6 dimensionless polar opening radii were determined by solving elliptical integrals and filament winding angles were calculated throughout the dome and cylindrical portions. Afterward, finite element analysis was performed to obtain mechanical properties by using the Ansys ACP module. As a result of the current study, it has been concluded that dome profile and filament winding angle are highly dependent on the polar opening radii. When the performance factor was considered, it has been determined that the optimum pressure vessel has 0.6 dimensionless polar opening radii. Moreover, it was observed that minimum equivalent stress, strain, deformation and inverse reverse factors have occurred in the pressure vessel with 0.6 dimensionless polar opening radii. Furthermore, it was showed that effective parameters in the mechanical performance of pressure vessels can be optimized to obtain strengthened and lighter structures. (c) 2022 Hydrogen Energy Publications LLC. Published by Elsevier Ltd. All rights reserved.